How can we use Red Pitaya boards for industrial applications?

-

Posted by

Red Pitaya Technical Editorial Team

, October 25, 2021

Red Pitaya Technical Editorial Team

, October 25, 2021

Why do we call Red Pitaya boards the “Swiss army knife for engineers”? Mainly because of their versatility, simplicity and small size, with different models and options, allowing users to pick the right tool for their needs and budget. The SIGNAL- and STEMlab units can be used in virtually any application requiring signal acquisition, generation and real-time signal processing, with the exception of very specific and high-end setups. While an actual Swiss army knife will offer you different options such as knife size, cork screw and other peripherals, the functional differences between the Red Pitaya models mainly concern sample rate and resolution.

What are we actually referring to when talking about versatility?

Basically, to the fact that Red Pitaya boards can be integrated in almost any setup with configurable RF in- and output requirements, within the sample rate and resolution limits of each model (up to 250 MS/s, 16-bit resolution and 60 MHz bandwidth). Besides general DAQ operation, this also allows them to perform the tasks of many standard instruments we can find in every electronics lab, such as oscilloscopes, LCR meters, spectrum-, Bode- and network analyzers. All these applications are included in the standard software package supplied with the Red Pitaya units, and are ideal for T&M purposes. Since all software is open-source and setup can be done using universal tools such as MATLAB, LabVIEW and Python, tailormade modifications can easily be implemented to adapt to specific user needs. Moreover, SCPI protocols ensure compatibility with instruments from other manufacturers. Again, this will not cover high-end applications requiring equipment with a much bigger price tag, but it will give any other standard instrument a run for its money. The open-source software and straightforward connectivity also make it possible to build new applications from scratch. An example of such an application, involving the development of an EMC measurements & teslameter project, can be found here.

How is Red Pitaya used in the industry?

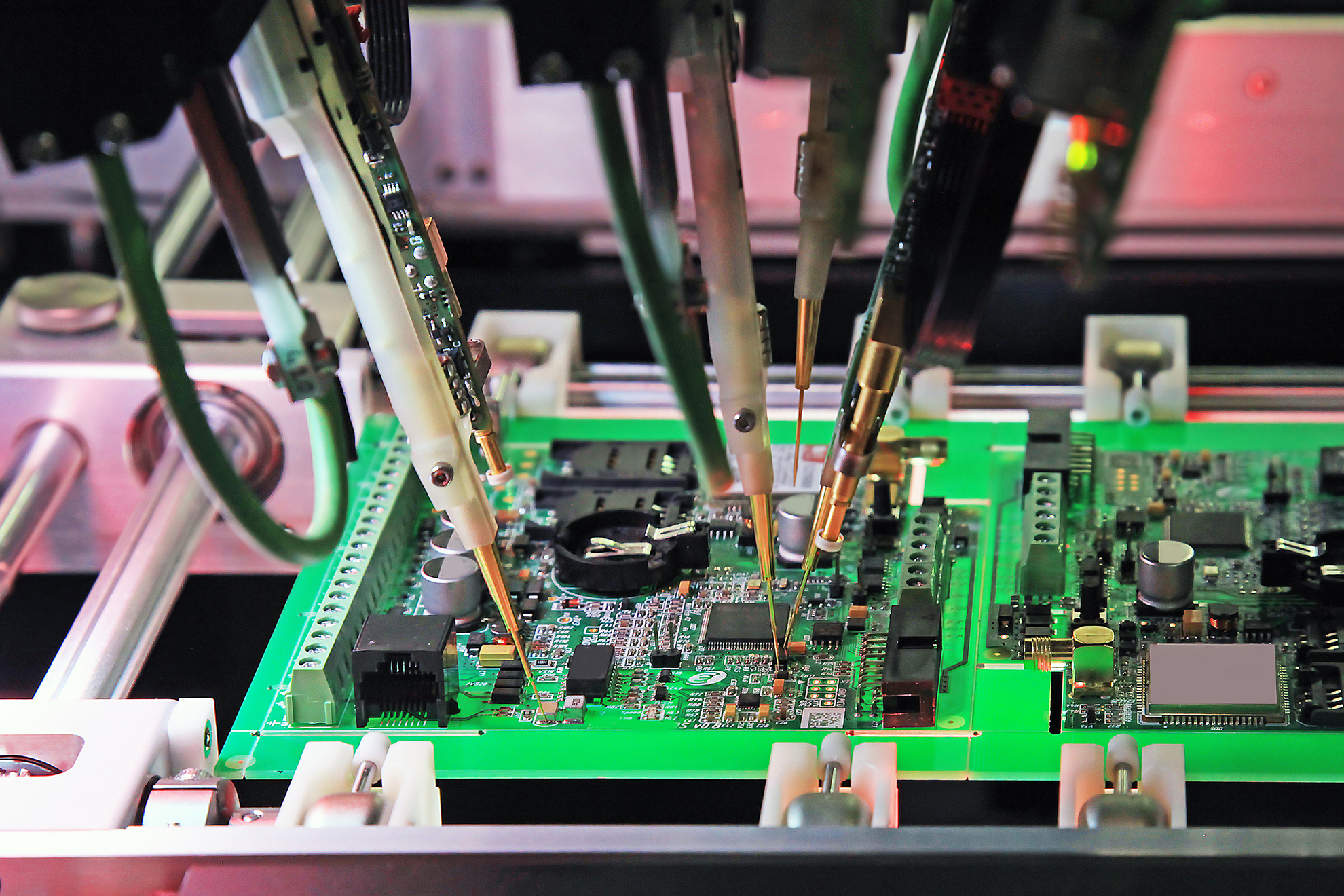

In the meantime, the industry has also been convinced by the functional aspects of Red Pitaya boards. When it comes to data acquisition and signal processing, OEMs are always looking for components with maximum performance in a small volume, and with the added value of their flexible configuration and connectivity, the Red Pitaya units have plenty to offer them. The naked board can easily be integrated into switchboards, control units, etc., and is sturdy enough to withstand standard operating conditions, with the possibility to develop special versions for specific environments. As such, Red Pitaya can satisfy the needs of a wide range of sectors, from the automotive industry, aerospace and defense, to R&D and telecommunications. One STEMlab unit can actually be found in space, aboard the ISS, integrated in a NASA atmosphere quality monitor. Other blog posts on this website show more examples of applications where a Red Pitaya board has successfully been integrated in operational high-tech equipment.

About the Red Pitaya Team

The Red Pitaya Technical Editorial Team is a cross-functional group of technical communicators and product specialists. By synthesizing insights from our hardware developers and global research partners, we provide verified, high-value content that bridges the gap between open-source innovation and industrial-grade precision.

Our mission is to make advanced instrumentation accessible to engineers, researchers, and educators worldwide.