Testing a High Precision, Wide Bandwidth DC Current Transducer with Red Pitaya

-

Posted by

Red Pitaya Technical Editorial Team

, January 20, 2022

Red Pitaya Technical Editorial Team

, January 20, 2022

Where, traditionally, AC-voltage was predominant in power generation, distribution and high-power applications, its DC rival is now playing an increasingly important role. This was already partly due to technological developments making it possible to combine the advantages of both systems, but is now accelerating thanks to the switch from combustion to electric vehicles, as well as to the energy transition and shifting trends in sustainable power generation and storage.

New or upgraded applications also bring along optimizations in the field of monitoring and data acquisition. One of the challenges lying ahead in this area is high-accuracy DC current measurement, with additional requirements to monitor higher harmonics and DC leakage currents where power converters are involved. In 2020, Uroš Platiše, Tomaž Kanalec and Mihael Mohorčič published a paper (High Precision Wide Bandwidth DC Current Transducer Based on the Platiše Flux Sensor, https://www.mdpi.com/1424-8220/20/15/4197) explaining the concept of a new DC current transducer, based on a single gapless core and an innovative Platiše Flux Sensor, and presented the test results of a prototype model.

Traditional DC current transducers are based on different physical principles, such as ohmic resistance (in the shape of shunts), magnetic field (Hall sensors and DCCT), or the Faraday effect. All of them have significant drawbacks, ranging from power dissipation, lack of galvanic isolation, limited accuracy and bandwidth, to DC offset and sensitivity to environmental conditions.

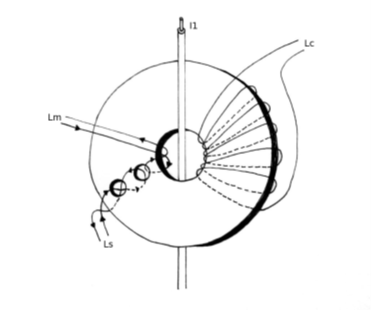

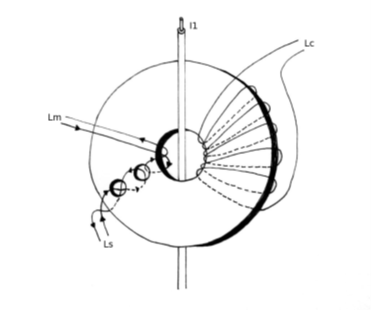

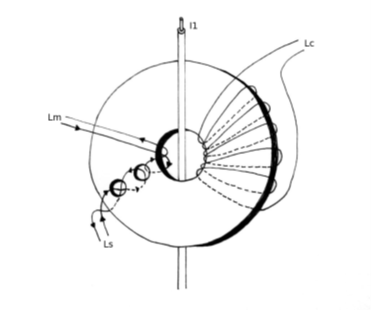

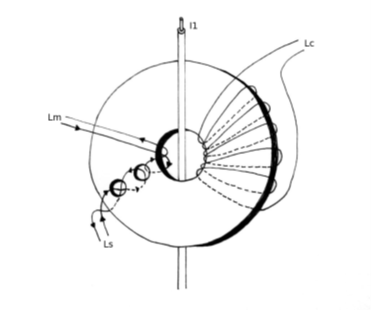

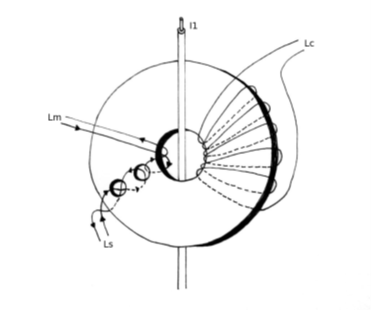

One of the first versions of a gapless zero-flux DCCT was developed at CERN during the 1970s, resulting in a reliable instrument with 100 ppm gain accuracy, 5 ppm linearity, 10 ppm offset error and temperature drifts of 1 ppm/K. These properties turned it into a gold standard for particle accelerators, providing precise beam current measurements, but leaving room for improvement in the field of bandwidth (limited to 10 kHz). Uroš Platiše designed a similar system, in which he is modifying the magnetic circuit locally by adding holes to the magnetic core and a “balanced” winding (Ls in Fig. 1 below, showing the general principle).

This additional winding can locally saturate the different branches of the circuit, introducing a virtual magnetic switch which forces the flux to change its path and increases the overall reluctance, without any mechanical interventions. This concept is called Current-Controlled Variable Reluctance, or CCVR. By redirecting the magnetic flux it can be sensed with an additional winding Lm in Figure 1. The added control circuitry, including a modulator, demodulator and low-pass filter, form a so-called Platise Flux Sensor (PFS), which output voltage which is directly proportional to the measured current I1. The PFS provides an electrically isolated DC-CT sensor featuring a compact and cost-effective design, high bandwidth (more than 800 kHz), high-accuracy measurement, in 0.01% to 0.1% class, for currents, ranging from a few A to several kA, and a wide dynamic range. The gapless concept provides high stability and immunity to external magnetic fields.

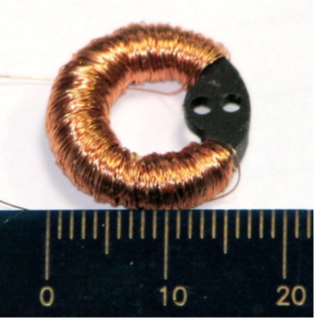

Needless to say, however, even the most brilliant ideas need to be tested, and that´s where Red Pitaya comes into the picture. For the concept functionality test, a DCCT prototype model 40A9R was produced with a nominal current range of ±40 A (see Fig. 2 below).

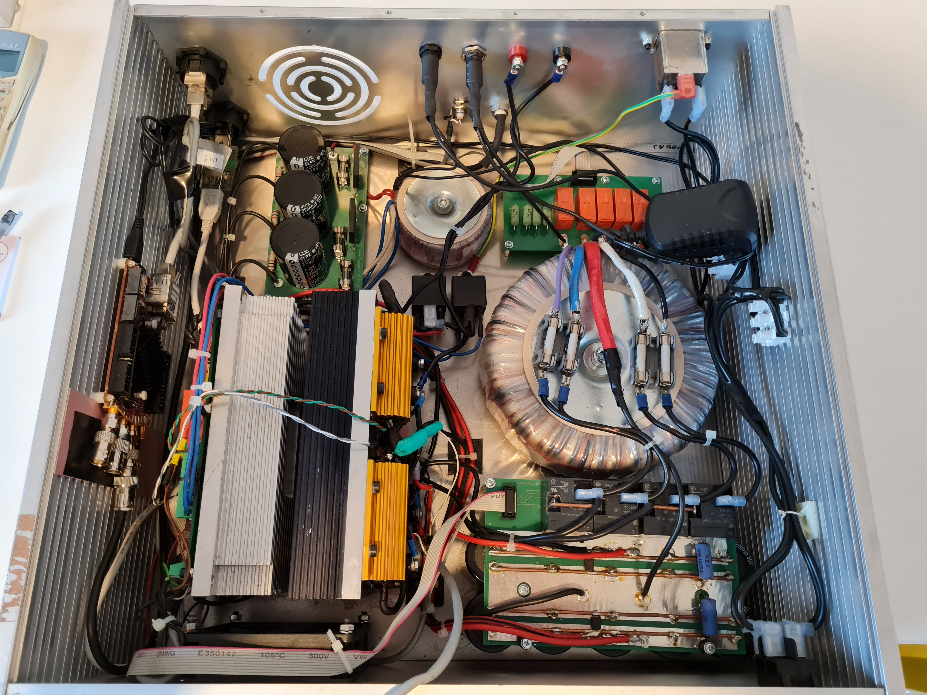

For the simulation output current, a tailormade 2 MHz 40A generator was designed. Since, besides producing the signal, testing cannot be conclusive without careful test data analysis, a Red Pitaya unit was integrated in the generator and its ADC function, with the traditional 125 MS/s sample rate and 60 MHz bandwidth, was used to transform analog input into reliable digital information.

And what do the test results show? Basically, that the first prototype of this sensor already outperforms similar sensors in many respects (see the original article for more detailed information). DC-CT initial test series was also tested at the Elettra Synchrotron in Trieste. Further development is ongoing to assemble cores for current ranges beyond 1000 A and a bandwidth of more than 10 MHz. A new test generator will probably have to be designed when this model sees the light, but without the need to purchase a new Red Pitaya board. Since its specifications still leave a considerable margin when it comes to measuring and sampling the increased nominal bandwidth, it will be possible to simply disconnect it and plug it into the new generator.

More info about the project can be found here.

About the Red Pitaya Team

The Red Pitaya Technical Editorial Team is a cross-functional group of technical communicators and product specialists. By synthesizing insights from our hardware developers and global research partners, we provide verified, high-value content that bridges the gap between open-source innovation and industrial-grade precision.

Our mission is to make advanced instrumentation accessible to engineers, researchers, and educators worldwide.