Autonomous Pipeline Inspection Robot: Low-Cost Acoustic Leak Detection

-

Posted by

Red Pitaya Technical Editorial Team

, December 10, 2025

Red Pitaya Technical Editorial Team

, December 10, 2025

.jpg)

Regardless of what you’re feeding through a pipeline, leaks will always be your worst enemy. Not just because whatever is seeping out of your pipes represents an obvious financial loss, but also because the gas or liquid might be a danger to the environment and public safety. This makes pipeline monitoring throughout the entire lifespan of the pipe essential to ensure structural health and detect any possible flaws before leaks occur. Needless to say, this is a challenging task when talking about kilometers and kilometers of pipeline, especially when access is difficult. In their project Development of a Pipeline Inspection Robot, Cardiff University’s Rosemary Palmer and her colleagues addressed this challenge, developing a low-cost autonomous robot to detect leaks from inside a pipe by means of acoustic emission (AE) sensing.

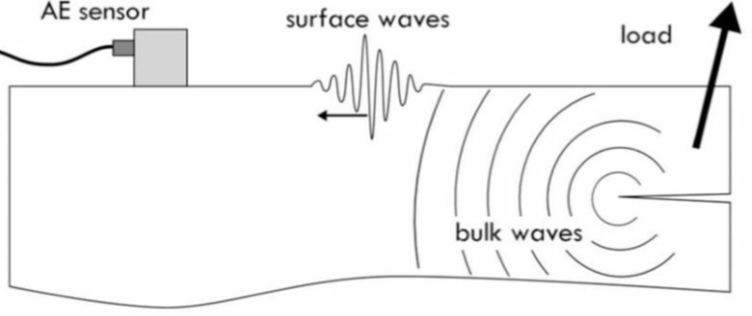

In contrast to ultrasound inspection, AE sensing is a passive monitoring technique that analyzes energy, as released in the form of waves and propagated through the pipe walls. These waves can be generated by a structural change, such as deformation or cracking, but also by turbulence at an existing leak orifice. The signal must then be picked up by an AE sensor, installed against the pipe wall. The basic idea of signal generation, propagation, and pickup can be seen in the figure below.

Figure 1 Surface wave generation, propagation and detection

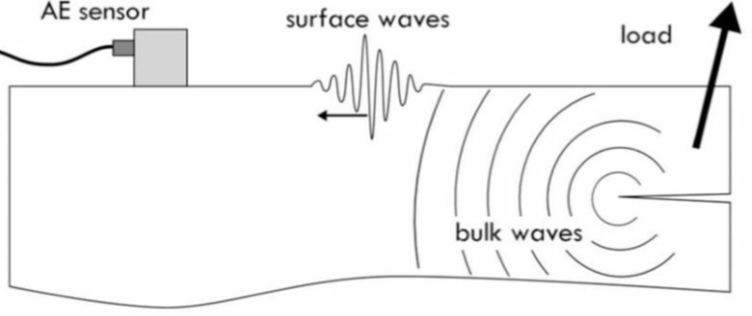

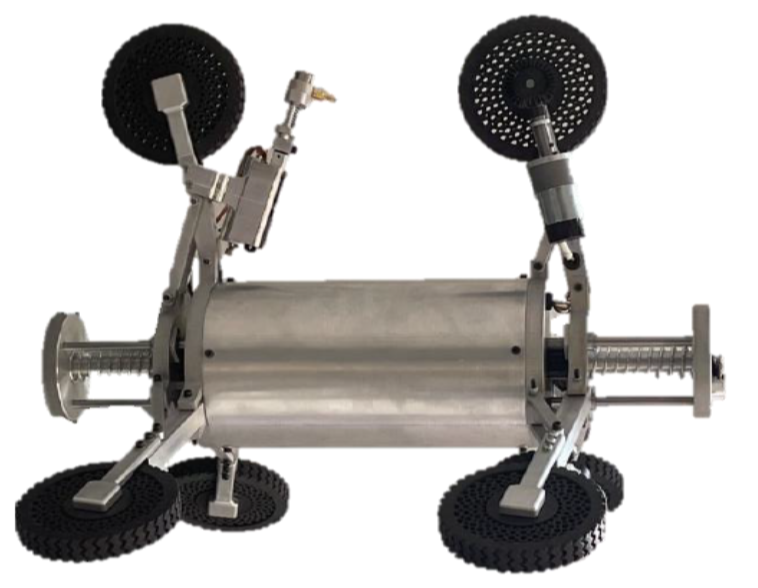

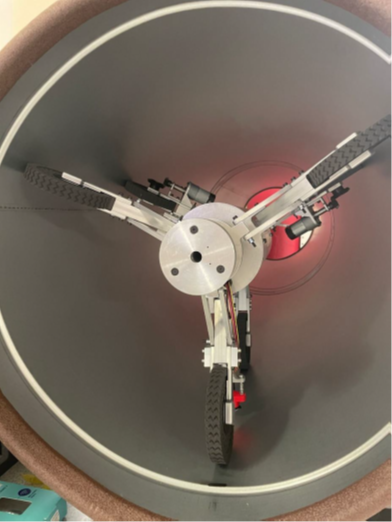

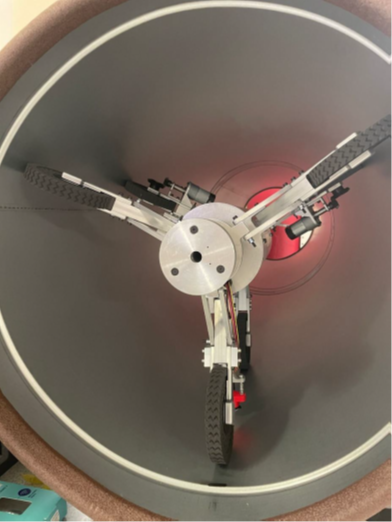

Logically, the detection range of such a system cannot be infinite, so a mobile chassis was developed to move the sensor over a virtually unlimited distance. Placing the robot inside the pipeline also made it independent of external access difficulties to the pipe wall surface. Several design types were taken into consideration, before finally selecting a wheel-type robot model with adaptable front and back wheel sets and the necessary electronics, motors, gears, and controllers to move autonomously up and down the pipeline. An AE sensor support arm was mounted on one of the wheel assemblies, as can be seen in the following figures.

Figure 2 Wheel-type robot model

Figure 3 Robot inserted in pipeline

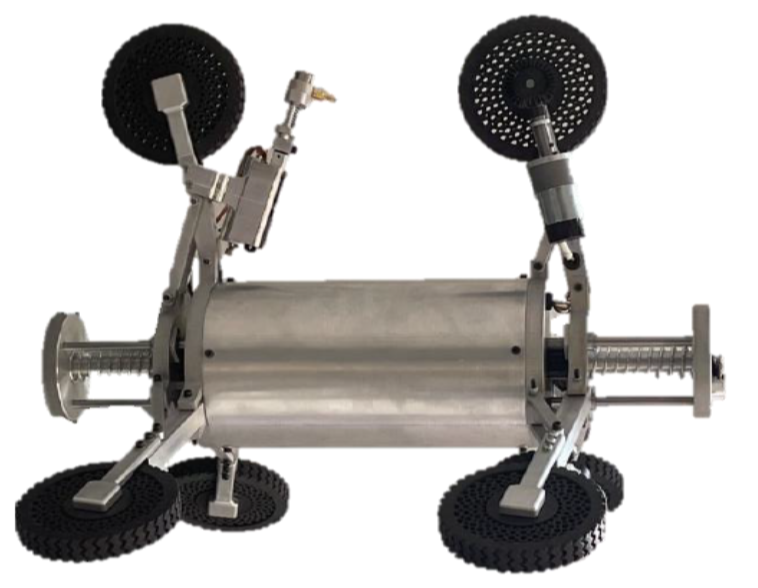

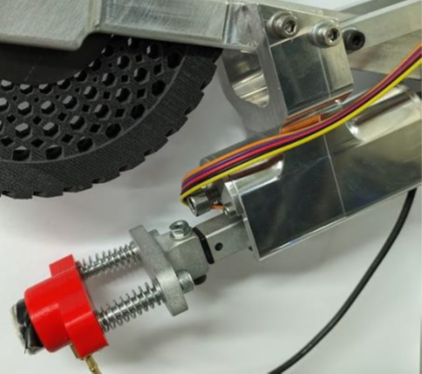

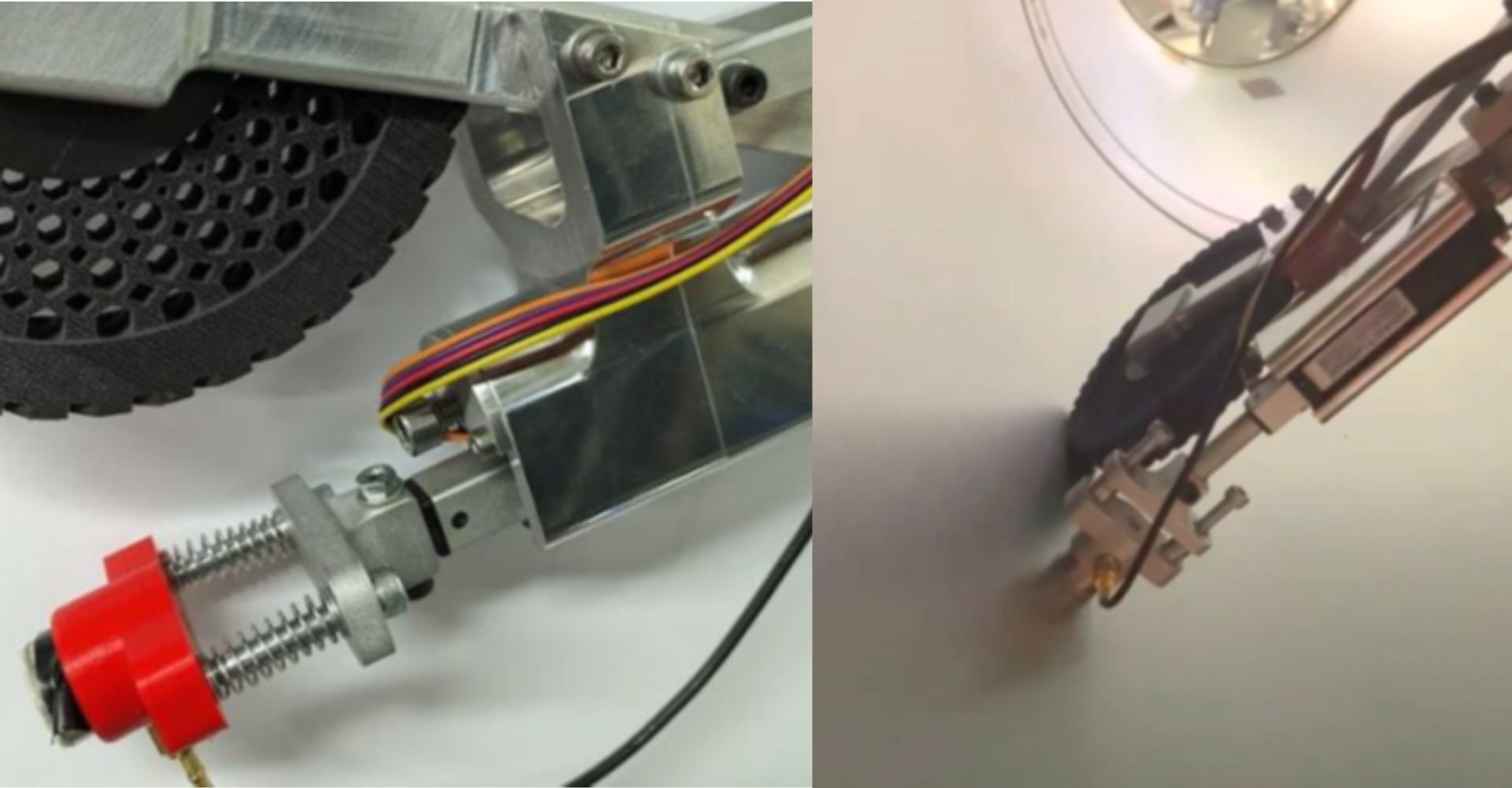

The AE arm was obviously a critical element in the leak detection robot, since it needed to ensure contact with the pipe wall at all times. Therefore, a linear actuator provided the necessary compression force and flexibility to couple the piezoelectric sensor – an R15 Alpha model with a permanent silicone face – to the pipe with sufficient surface contact.

Figure 4 AE sensor arm detail and coupling

Since an initial study showed that the AE signal, generated by the sensor, was too weak to be read with sufficient resolution, a Mistras preamplifier was included in the design. Picking up and sampling this amplified signal for data acquisition was then a simple job for a Red Pitaya STEMlab 125-10 board. Signals were processed in time-driven mode, capturing RMS values over fixed intervals for leak proximity analysis.

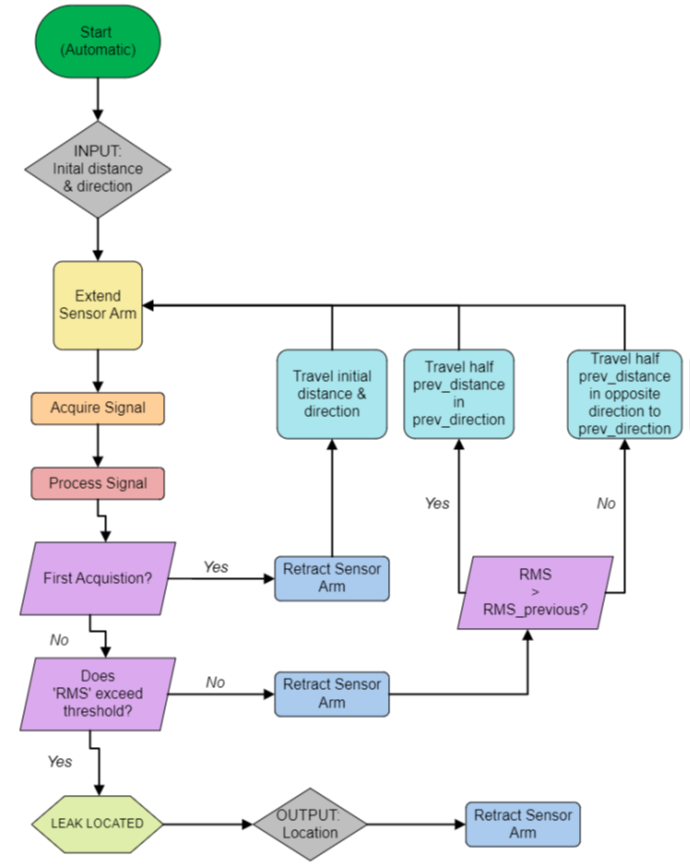

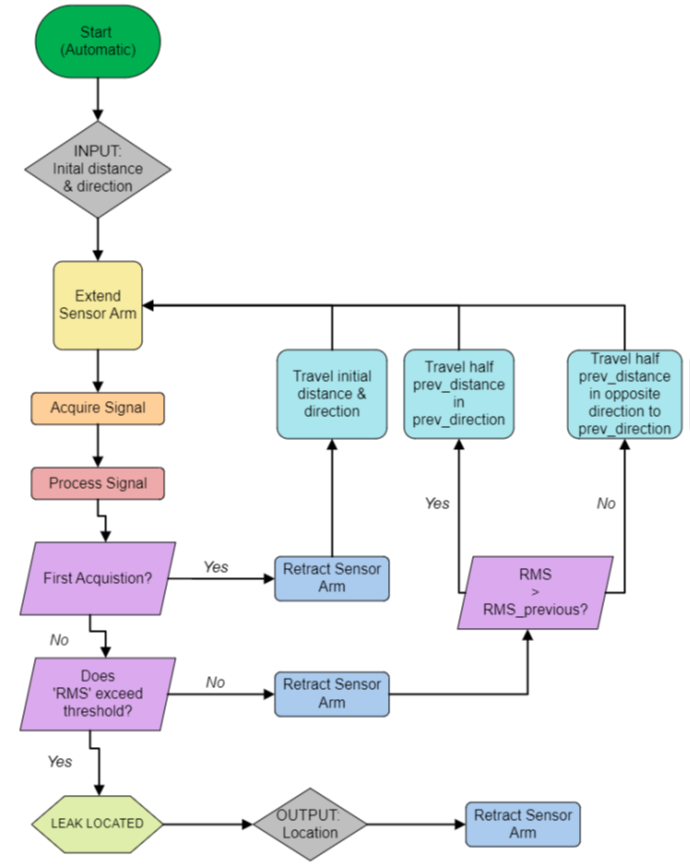

The robot was developed for autonomous leak detection, using an iterative technique described in the following figure, in which the robot compares RMS readings from two different positions in the pipe to determine the subsequent direction and distance of travel.

Figure 5 Autonomous Control Flowchart

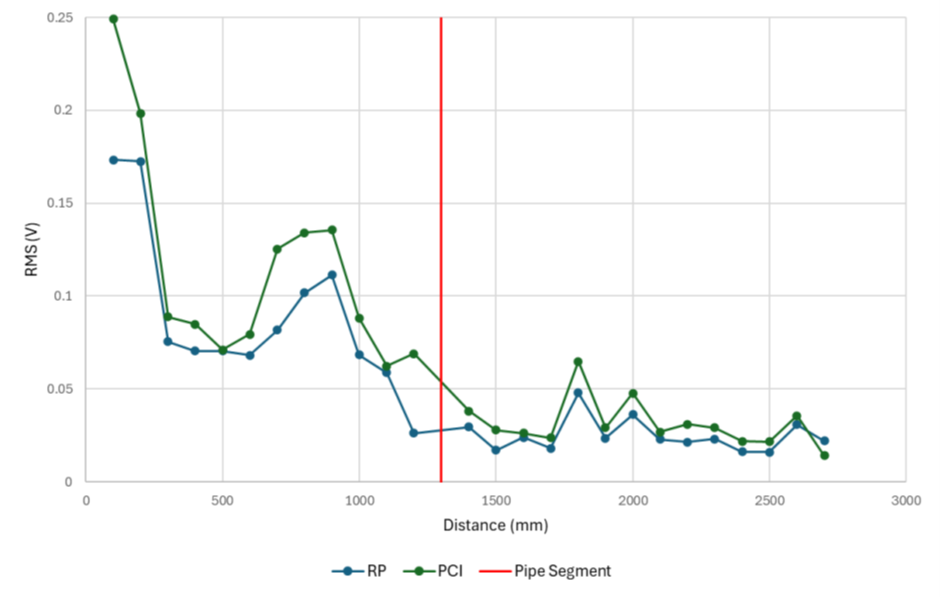

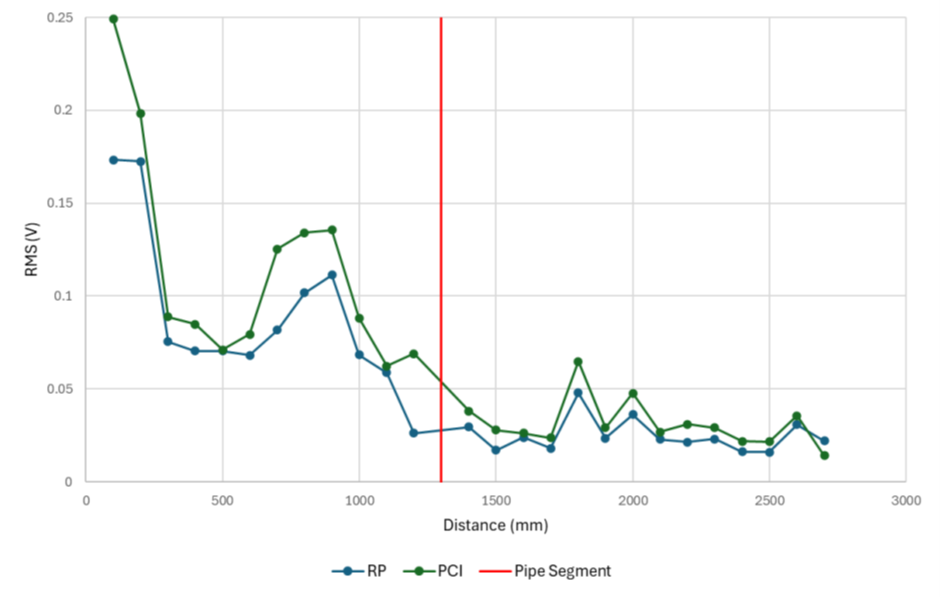

The first step in the test phase of the system was the evaluation of signal attenuation in the pipeline material. To certify the test setup, a signal-generating actuator was mounted on a galvanized steel pipe in 26 different positions to simulate the acoustic signal of a structural change or leak turbulences. The results of this test showed an exponentially decreasing trend of the RMS value with increasing source-sensor distance, with the exception of two spikes, generated by standing waves due to the reflection by the pipe extremities.

Figure 6 RMS value attenuation

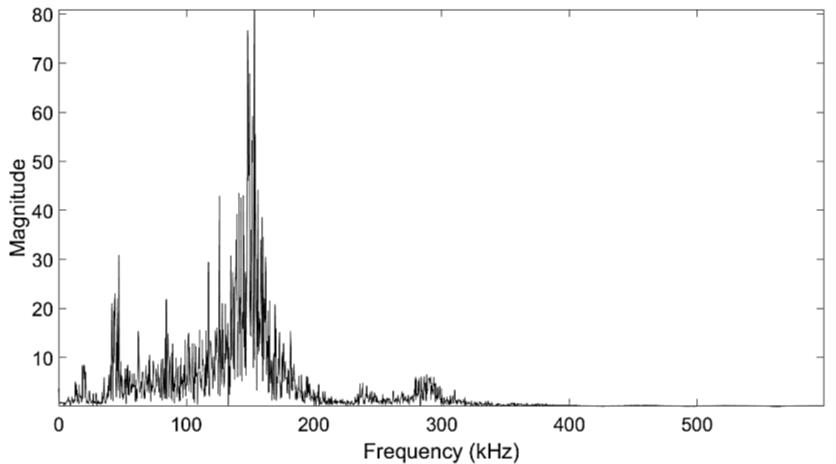

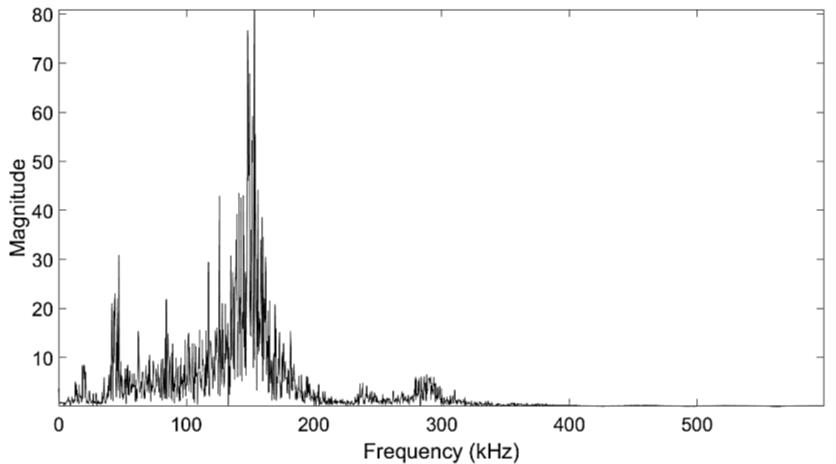

After the attenuation study, a leak detection test was carried out on a stainless-steel pipe, in which a 2 mm by 5 mm hole simulated a leak with pressurized air flowing through the pipe at a pressure of 6 bar. The AE sensor was coupled with the pipe from the outside in five different positions, picking up characteristic frequencies between 20 and 300 kHz, with the strongest components at 40 and 150 kHz.

Figure 7 FFT spectrum at 200 mm source-sensor distance, acquired by a STEMlab 125-10 board

The results of the tests, as performed by the team at Cardiff University, validated the design of a robot for autonomous leak detection in pipelines by means of AE sensing, integrating a Red Pitaya board into a compact system. Where the attenuation results show that leaks can be detected up to a distance of around 2 m – which also depends on the pipe material – the control system of the robot then allows leak location with an accuracy of 30-60 mm, using an interactive AE location technique. Moreover, since these results were achieved on a budget of just under £2,000, it wouldn’t break the bank to develop a life-size prototype for final validation. And if a higher sampling resolution can help to improve detection range and accuracy, then it’s good to know that the 10-bit version of the STEMlab device is only one of a wide range of boards produced by Red Pitaya.

About the Red Pitaya Team

The Red Pitaya Technical Editorial Team is a cross-functional group of technical communicators and product specialists. By synthesizing insights from our hardware developers and global research partners, we provide verified, high-value content that bridges the gap between open-source innovation and industrial-grade precision.

Our mission is to make advanced instrumentation accessible to engineers, researchers, and educators worldwide.