DR-RINS: Digital real-time relative intensity noise suppressor for pump–probe spectroscopy and microscopy

-

Posted by

Red Pitaya Technical Editorial Team

, July 7, 2021

Red Pitaya Technical Editorial Team

, July 7, 2021

Transient absorption and stimulated Raman scattering microscopy are techniques that sense tiny perturbations to a probe laser beam, induced by a pump beam, to create their images, which makes them extremely sensitive to laser relative intensity noise (RIN), especially in fiber lasers. The suppression of this noise can be done using software adaptive noise cancellation (ANC) on digitized signals, although this introduces a considerable delay, due to the time required for digitization and post-processing. Hardware noise suppression, using FPGAs, is a clever way of doing this in real-time, as described by Jesse Wilson, Saurabh Gupta, Erkang Wang and Steven Derrien in Review of Scientific Instruments.

Contrary to bulk laser sources, where RIN cancellation can be done by modulating the pump beam at >1 MHz, the broad bandwidth and high-frequency RIN in fiber lasers requires ANC through balanced detection. An initial approach, using high-speed ADC and adaptive filtering for active RIN cancellation, was limited by the relatively high ADC noise (in comparison with the RIN) and the post-processing time needed for the acquired data. These limitations can be overcome by adaptive filtering directly on the hardware, in this case, a field-programmable gate array (FPGA), which is extremely suitable for real-time processing due to the low latency and high bandwidth computations. In this case, a Red Pitaya STEMlab 125-14 was inserted between the photodetectors and a lock-in amplifier. Besides the improvement provided by this change in approach, the STEMlab also offers a significantly lower noise floor compared to the ADC in the initial design.

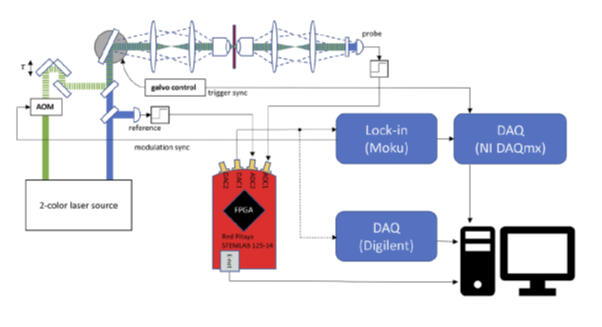

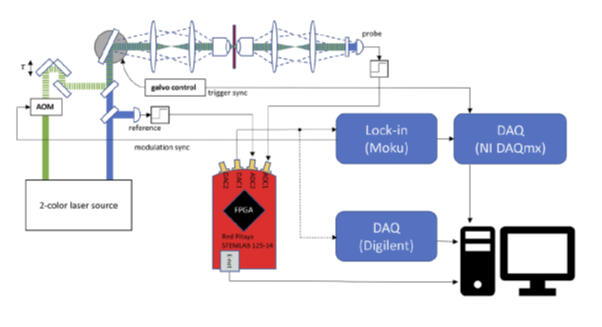

Figure 1 shows the experimental setup, used for this development, where the STEMlab receives and converts inputs from the photodiodes, located before (reference) and after (probe) the microscope. After running the digitized signals through an ANC on the FPGA, the resulting analog output is fed to a hardware lock-in amplifier (Moku) and synchronized to the pump modulation frequency or a high-speed DAQ device.

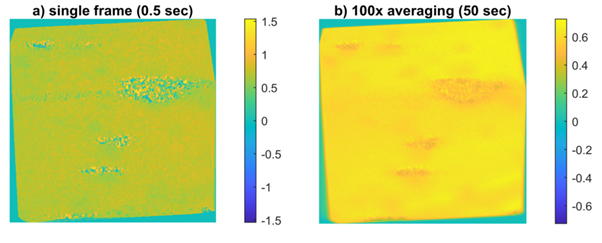

One application example of this setup is real-time imaging with a hardware lock-in, where the DR-RINS system was tested as a drop-in pre-filtering device in front of a hardware lock-in amplifier to enable real-time imaging of a sample of crushed Bi4Ge3O12 (BGO), with a probe delay set to τ = 0. The output of the lock-in, along with scan position monitor signals, was collected with a multi-channel DAQ device, and an image formed using the MATLAB griddata () function to map the signal to the corresponding x- and y-coordinates. Figure 2 shows the results of both single acquisition and a 100-frame average, acquired in <5 min.

The test results on BGO show a considerable SNR-enhancement, obtained in real-time using the DR-RINS system, producing an analog output, compatible with a conventional lock-in amplifier. Despite the limitations, due to detector noise, transient absorption imaging was possible under conditions that would not allow the use of a lock-in amplifier alone (i.e., high RIN levels, combined with the effects of fast, resonant scanning of the beam). The most obvious advantage with the use of FPGA RIN filtering is the real-time ANC, which provides significantly faster imaging, even with a noisy fiber laser source. The approach of transferring ANC and lock-in detection to the hardware allows a reduction of imaging time from ∼6 h down to just ∼5 min.

We've since received an updated TA image of BGO and UV glue which is shown in Figure 3. The first row from left to right shows a delay scan of BGO TA signal (average signal of the whole FOV), a TA image without FPGA noise canceling (this image consists of 1MHz TA signal), and a TA image with the FPGA noise canceling. They are taken at a different time delay from -1.8ps, -0.8ps, 0ps, 0.3ps and 1p. you can see that the TA image intensity depends on time delay. Ops have the largest intensity. The second row follows the same order on a sample of a stripe of UV glue.

.jpg?width=1089&name=TA%20image%20of%20BGO%20and%20UV%20glue%20(002).jpg)

Since this is setup can be inserted as a plug-and-play device, it will certainly find many applications for RIN-denoising in experimental techniques, relying on the detection of small perturbations in probe laser beams, with Red Pitaya at the heart of the action.

For the full article click here.

About the Red Pitaya Team

The Red Pitaya Technical Editorial Team is a cross-functional group of technical communicators and product specialists. By synthesizing insights from our hardware developers and global research partners, we provide verified, high-value content that bridges the gap between open-source innovation and industrial-grade precision.

Our mission is to make advanced instrumentation accessible to engineers, researchers, and educators worldwide.